Residential/City

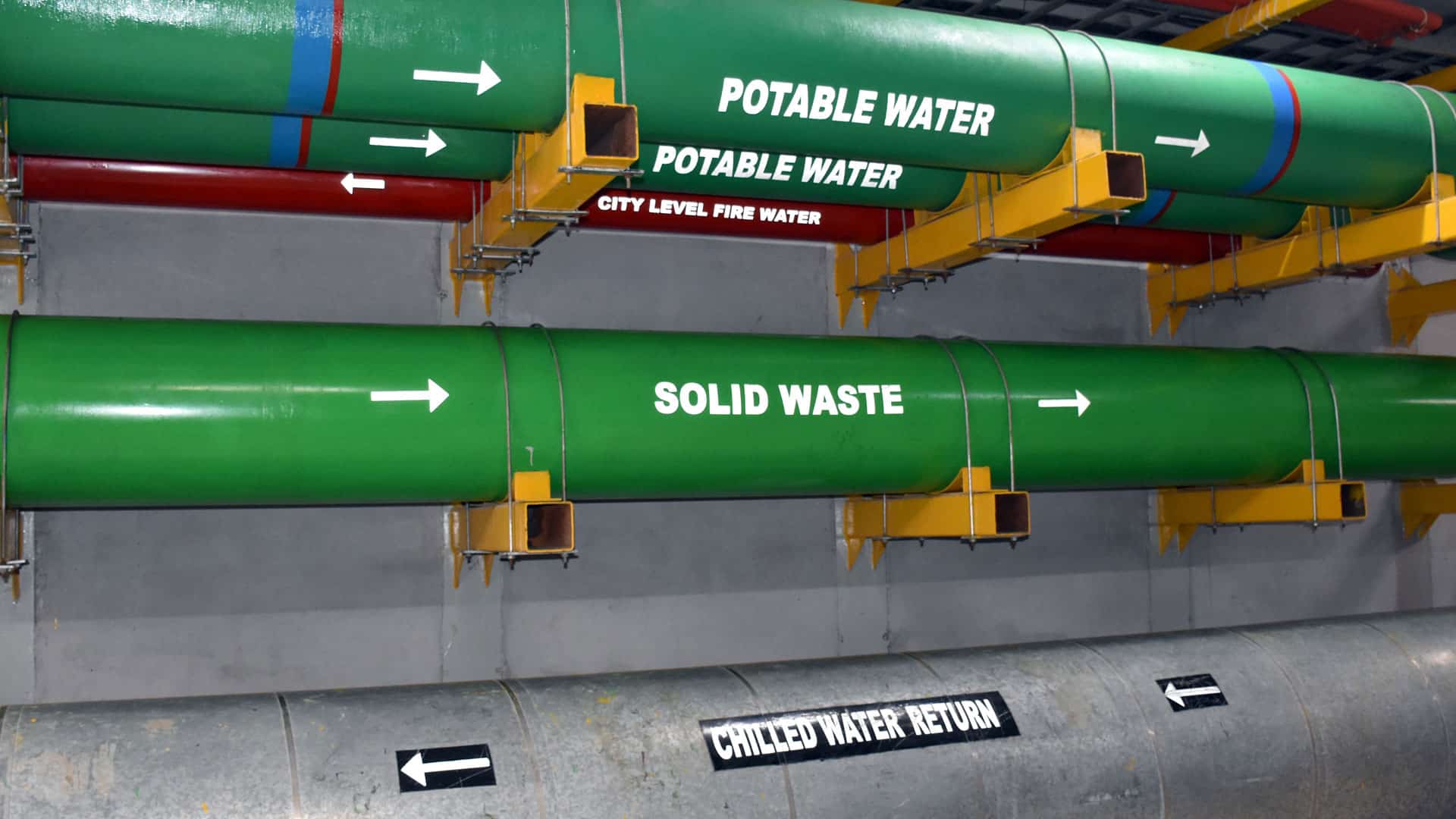

Our automated pneumatic waste collection system takes waste management to a new level underground. Say goodbye to the smell, mess, and inefficiencies of traditional waste management. With the Envac system, residents can enjoy cleaner, more attractive cities while benefiting from enhanced safety thanks to reduced human contact with waste materials. Cities and regions can optimise their waste operations, lower the risks associated with traditional kerbside pickup, and slash transport emissions. By streamlining waste collection, Envac improves the environment and quality of life in residential areas, making them more pleasant and healthier places to live.