Efficient hospital waste management is a critical aspect of running a hospital smoothly. Traditionally, many hospitals have relied on manual procedures or gravity chute systems to dispose of waste and linen, but these methods come with intrinsic risks and inefficiencies.

Contaminated materials piling up or clogging within chutes can lead to the spread of harmful pathogens, adversely affecting the health of everyone involved. However, recent advancements in pneumatic conveying technology present an innovative solution: the adoption of automated waste and linen removal in hospitals.

The Limitations of Gravity Chutes

While gravity chutes have long been a standard method for hospital waste disposal, their outdated design presents significant challenges in modern healthcare settings.

These chutes rely solely on vertical drop, making waste management inflexible and increasing the risk of contamination, blockages, and inefficiencies.

Over time, trapped waste and linens can lead to hygiene concerns, maintenance issues, and operational disruptions, ultimately affecting hospital efficiency and patient care.

Key Limitations of Gravity Chutes:

- High risk of contamination: Waste and linens can get trapped within the chute, creating a breeding ground for bacteria and pathogens. This increases the risk of airborne transmission and cross-contamination within the hospital.

- Frequent blockages: Materials that do not slide smoothly down the chute can accumulate, causing clogs that require manual intervention and costly maintenance.

- Limited waste separation: Traditional chutes do not support waste sorting for recyclables, hazardous waste, and soiled linens, making compliant and sustainable disposal more difficult.

- Restricted system design: Because gravity chutes rely on vertical movement, they can only be installed in buildings with the right structural layout, limiting their placement and efficiency.

- Operational disruptions: When a chute becomes blocked or contaminated, staff must divert time and resources away from patient care to address the issue.

- Unpleasant odors and pest attraction.: Waste accumulation at the bottom of the chute produces foul odors and attracts pests, further compromising hospital sanitation.

By contrast, pneumatic waste removal systems eliminate these risks by offering a fully enclosed, automated solution that enhances hygiene, improves efficiency, and supports sustainable waste management in hospitals.

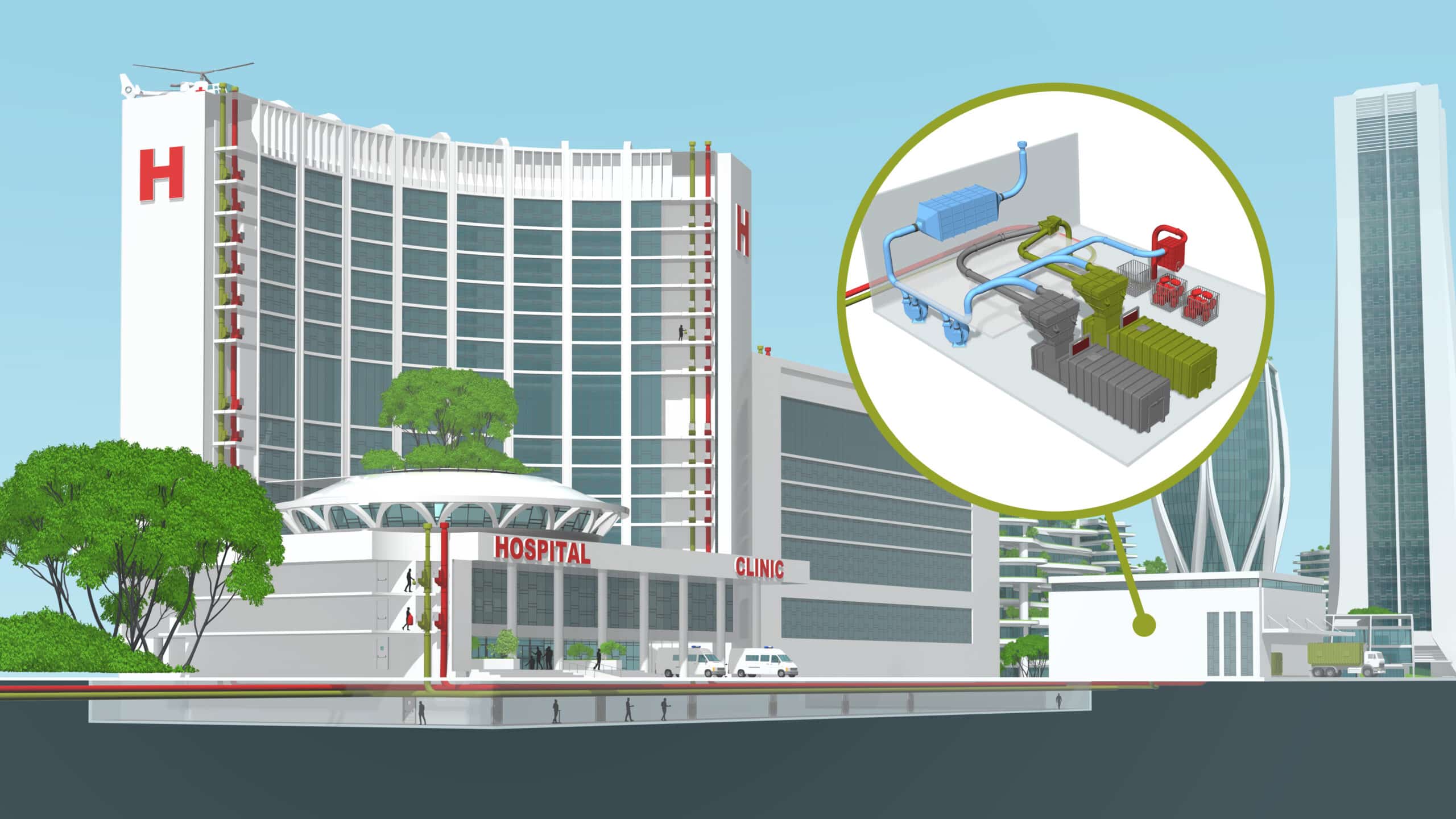

Introducing Automated (Pneumatic) Tube Systems

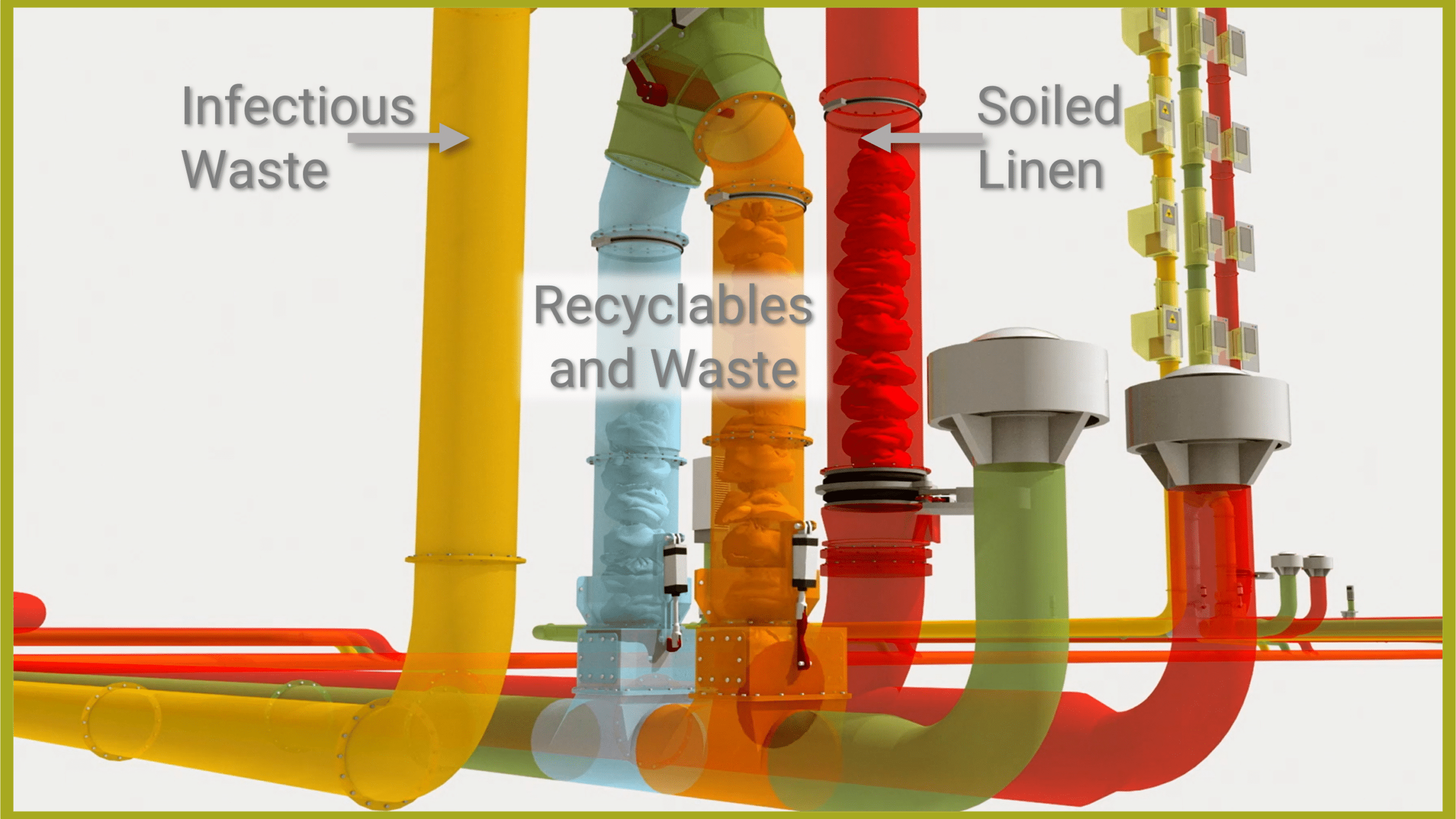

Pneumatic waste and linen conveying systems revolutionize hospital waste management by offering a superior alternative to traditional gravity chutes. Unlike gravity-based disposal methods, which are restricted to vertical movement, pneumatic tube systems can transport waste and linen in any direction, allowing for direct delivery to trash compactors, laundry facilities, or designated collection points—even across multiple buildings.

This fully automated, enclosed system eliminates the need for manual handling, significantly reducing the risk of cross-contamination, infection, and workplace injuries.

By streamlining waste transport, hospitals can enhance operational efficiency, optimize staff workflow, and maintain a consistently hygienic environment, regardless of the facility’s layout or complexity. For hospital facility managers, this technology ensures a seamless, sanitary, and future-proof approach to medical waste and linen removal.

1. Streamlined Waste Management Process

Automated waste and linen removal systems redefine efficiency in hospital waste management by eliminating the need for manual transport. With the innovative Q-Chute™, entire cartloads of waste, recyclables, or soiled linens can be quickly and securely loaded into the system through a discrete access door.

Unlike traditional methods that require frequent handling, the system’s hidden staging area temporarily holds the materials before automatically time-releasing them into the pneumatic conveying system.

This seamless automation reduces manual labor, minimizes hallway congestion, and enhances overall hospital workflow. By removing the burden of waste collection from staff, hospitals can improve efficiency, lower operational costs, and allow personnel to focus on patient care and critical medical tasks.

2. Enhanced Infection Control

Automated pneumatic waste and linen systems play a crucial role in infection prevention by eliminating common contamination risks associated with manual waste handling. The fully enclosed, closed-loop system prevents airborne pathogens, bacteria, and contaminants from spreading throughout the hospital.

By removing waste and soiled linens at the source and transporting them directly to designated disposal or laundry areas, these systems minimize exposure for patients, visitors, and healthcare workers.

The elimination of waste accumulation in hallways and storage areas also reduces breeding grounds for infections, helping hospitals maintain a safer, more hygienic environment while supporting compliance with stringent health and safety regulations.

3. Intelligent Clog Detection and Real-Time System Monitoring

Envac’s advanced pneumatic conveying technology goes beyond simple automation, integrating intelligent clog detection and real-time system monitoring to ensure uninterrupted waste and linen transport. The system is equipped with strategically placed sensors throughout the ductwork, continuously tracking movement and detecting potential obstructions before they become major issues.

In the rare event of a blockage, the system automatically shuts down only the affected load stations, preventing operational disruptions while keeping the rest of the system running efficiently. This targeted isolation minimizes downtime and allows maintenance teams to address the issue quickly.

Hospital personnel can monitor system performance in real-time from an on-site command center or remotely via a secure, web-based interface, ensuring proactive system management and optimization.

The future of hospital waste management.

Efficient waste and linen management is essential for maintaining hospital hygiene, ensuring patient safety, and optimizing staff productivity. Traditional gravity chutes come with inherent challenges—clogs, contamination risks, and limited transport capabilities—that can compromise facility operations. In contrast, pneumatic tube systems revolutionize hospital waste handling by offering:

- Automated transport, reducing manual handling and labor costs.

- Enhanced infection control, preventing airborne pathogen spread.

- Intelligent clog detection, minimizing disruptions and optimizing system performance.

Contact Envac North America directly to learn more about automated waste and soiled linen removal systems and how they can streamline the collection, transport and removal of waste and linen from your facility.

Our systems remove infectious materials from corridors and elevators, decrease elevator requirements, reduce staff injuries, and increase profitability by reducing FTE’s, workers compensation claims and infection rates.

You can reach us at get-facts@airconvey.com or 302-266-0555.

Lets Talk

Do you want to know more about Envac? Simply submit the form and your local Envac office will be in touch as soon as possible.