A dedicated system for infectious healthcare waste

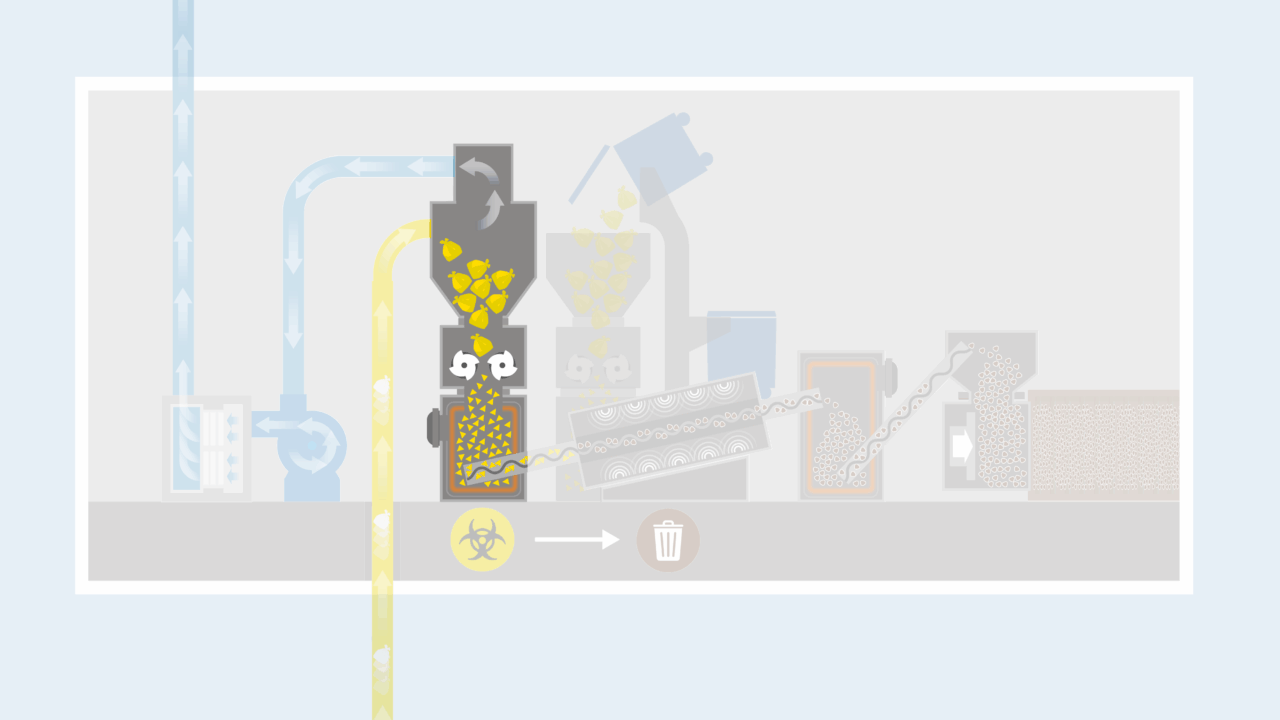

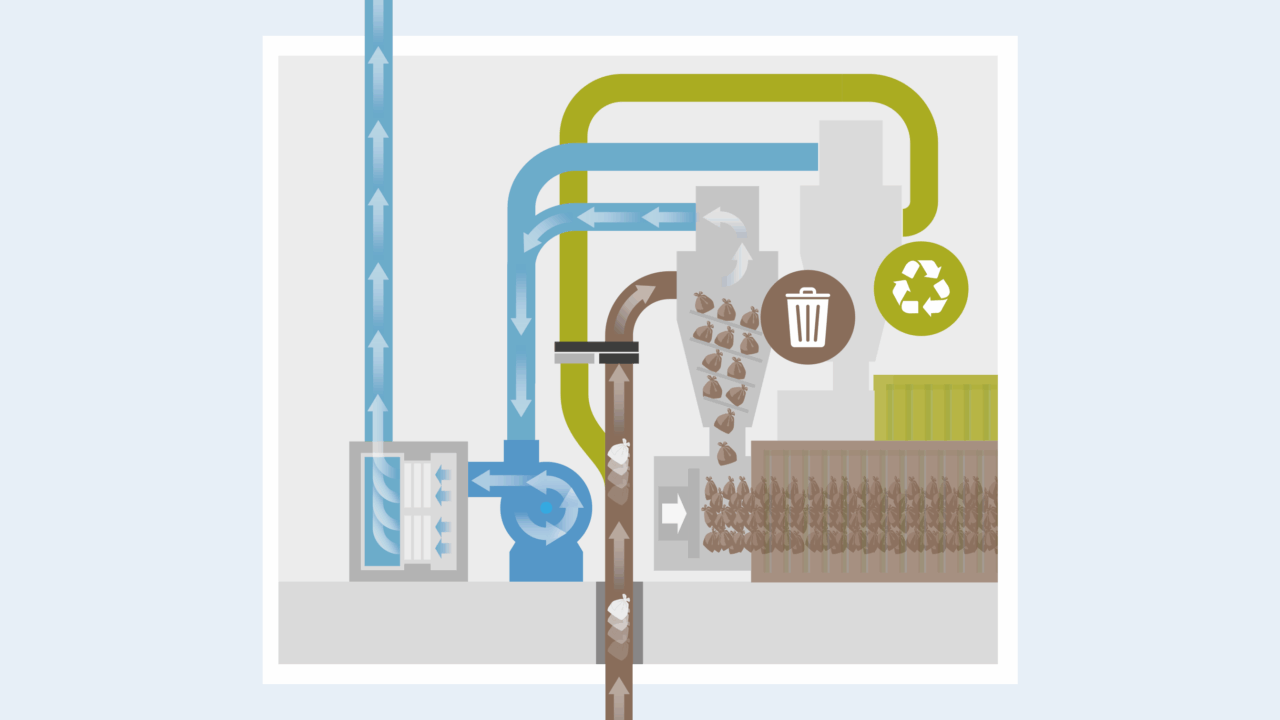

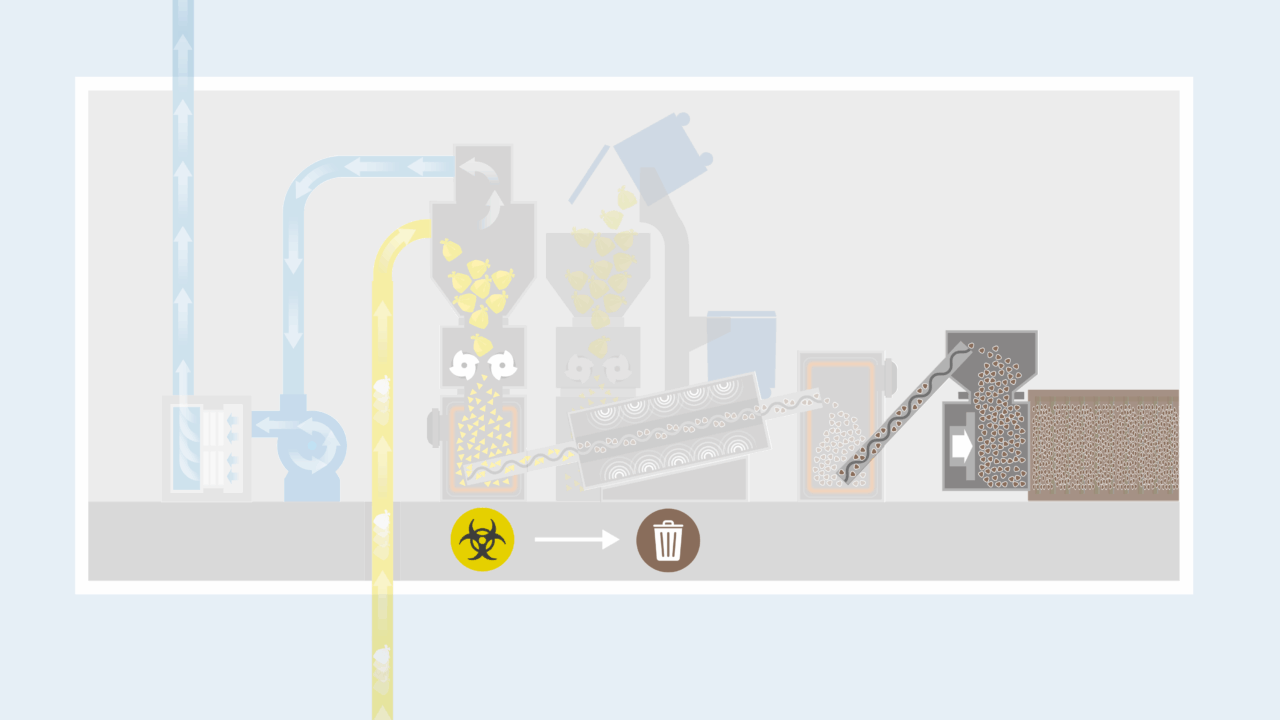

The Envac IWC system is a dedicated pneumatic collection system engineered specifically for infectious and hazardous healthcare waste fractions. It is configured as a completely separate network that does not share pipes or equipment with other Envac systems in the same hospital.

By separating infectious waste from general healthcare waste streams and handling it in a closed, automated system, IWC addresses one of the most critical challenges for hospital-acquired infections: the movement and manual handling of contaminated materials.