Boost productivity, minimise downtime, and cut costs with PAC’s advanced pneumatic trim and matrix waste removal systems. Designed for a variety of industrial applications—including wide web, narrow web, non-woven, film and sheet, paper, and paperboard—our solutions support manufacturers, printers, and converters in achieving more efficient operations and sustainable waste management.

Key benefits of PAC’s industrial waste removal systems

Decreased downtime

Cost savings & waste reduction

Lower labour costs

Increased productivity

PAC’s streamlined pneumatic trim and matrix waste removal systems enable companies to enhance output by eliminating production inefficiencies.

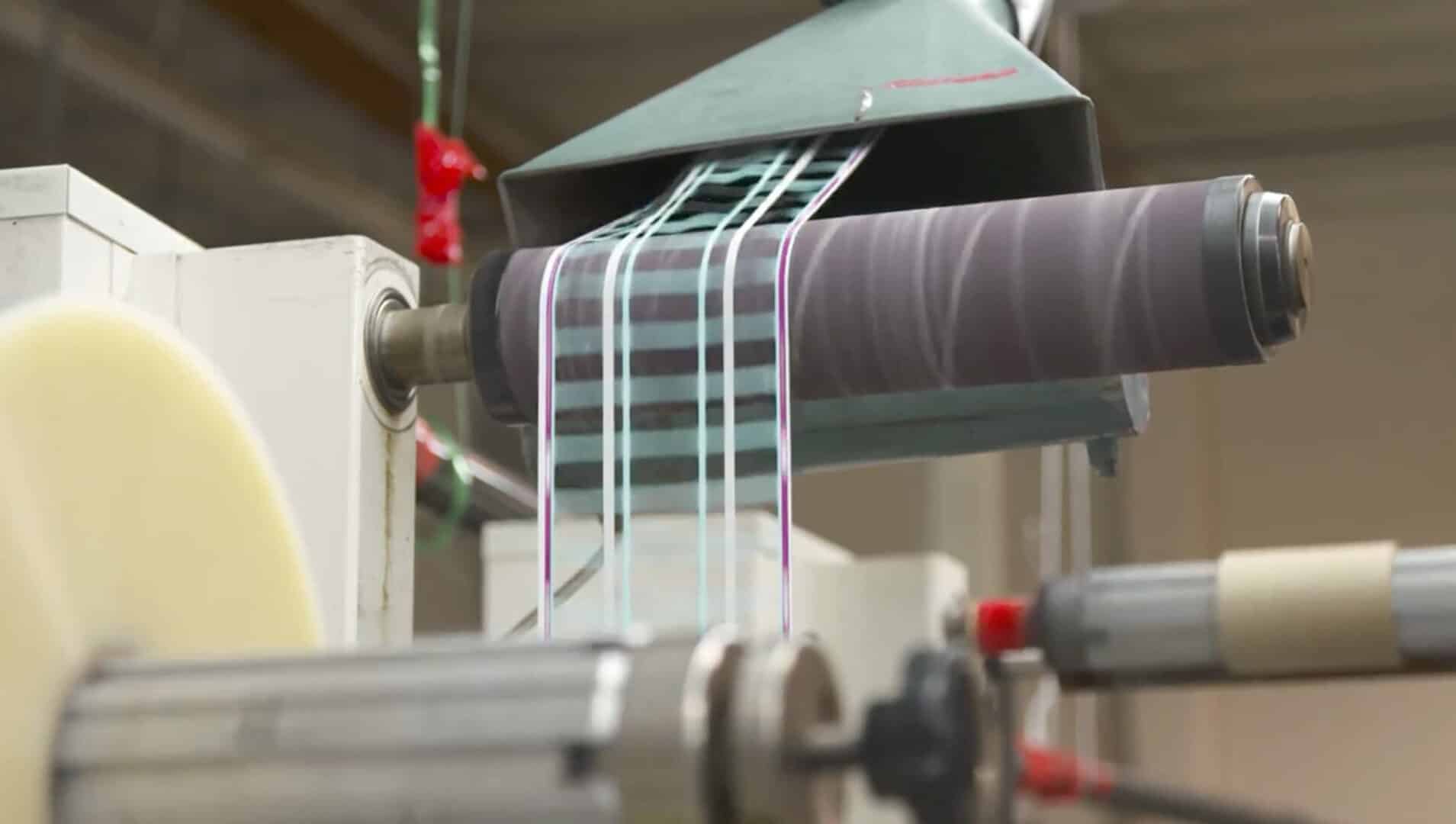

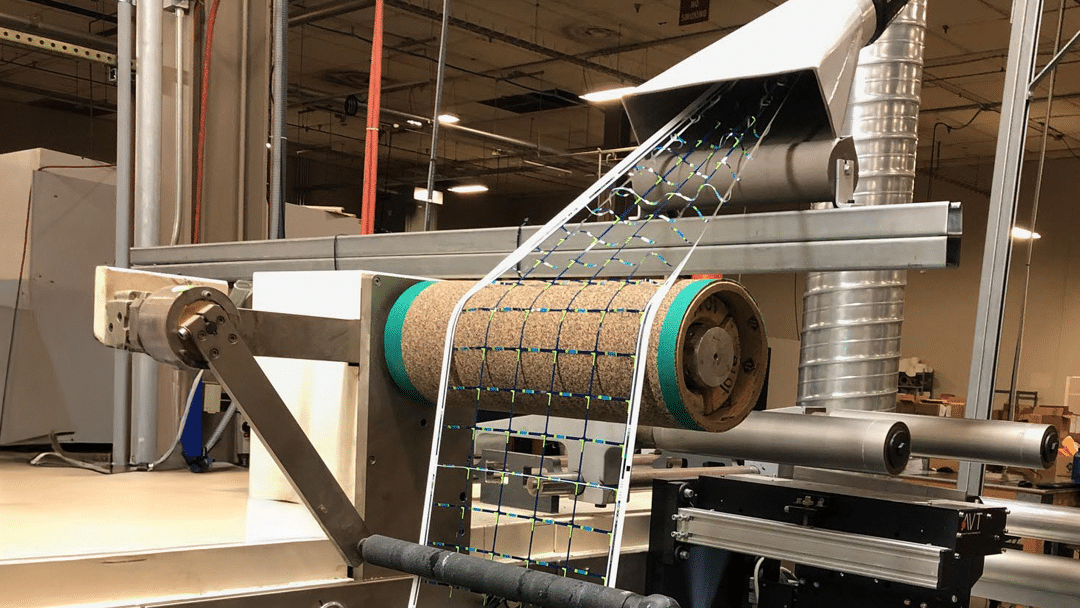

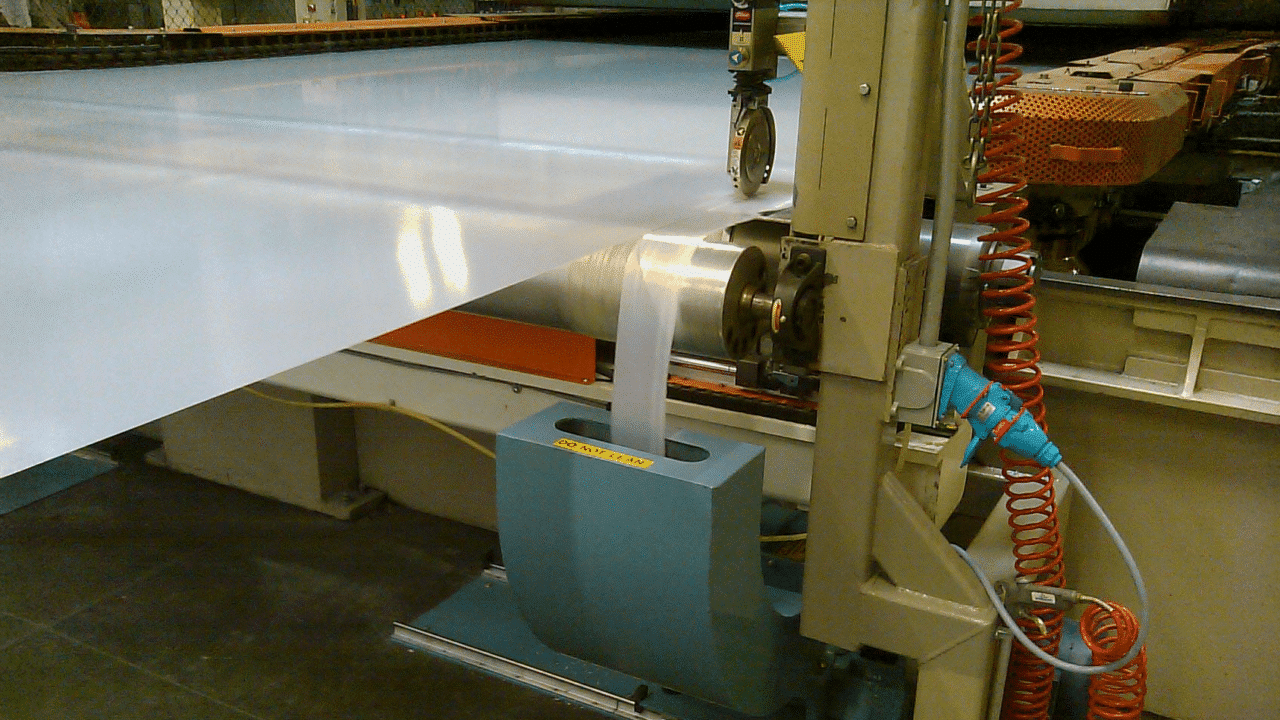

- Matrix Waste Removal – Our inline cutter/fan matrix removal systems capture waste directly at the press, chopping it into smaller pieces for easy disposal. This prevents press stoppages, maintains registration, and supports higher press speeds without the risk of jams or tension breaks.

- Trim Removal – Operating at high speeds, PAC’s trim removal systems improve product quality by eliminating edge tugging and ensuring clean, precise cuts.

Decreased downtime

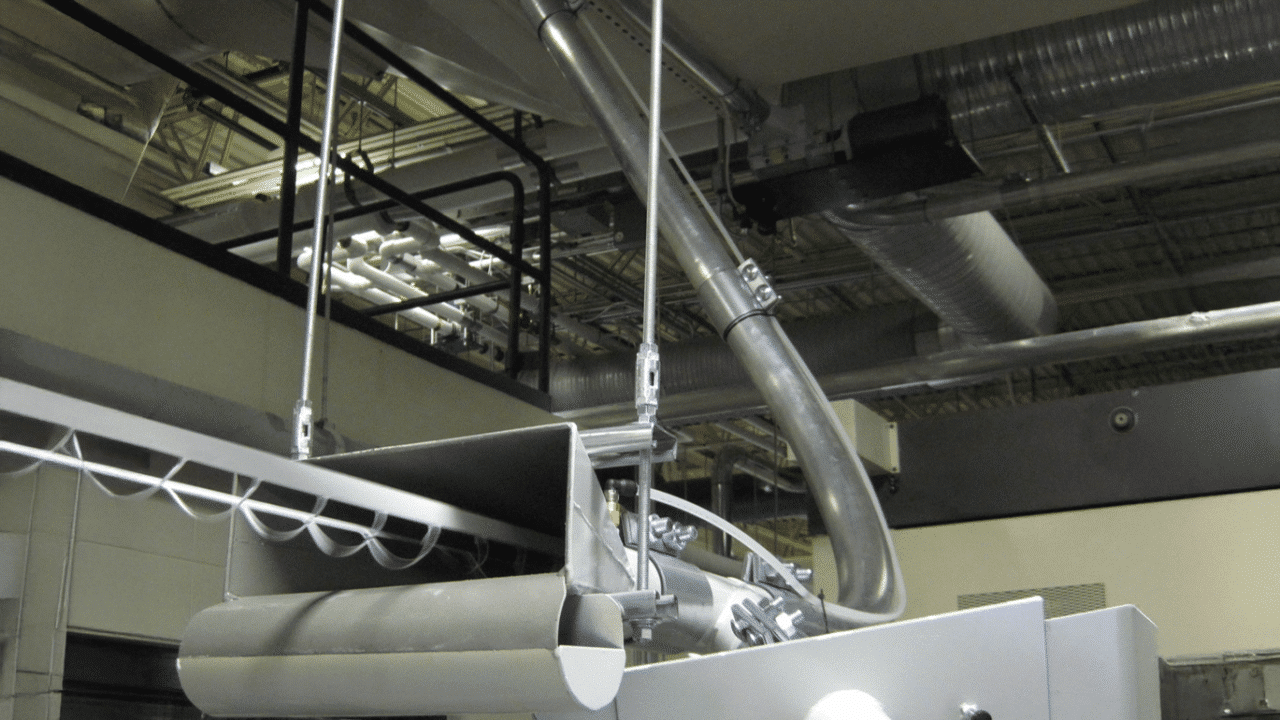

Our systems are designed to prevent common production bottlenecks such as clogs and jams, ensuring continuous operation.

- Prevent Clogging – PAC’s technology chops trim and matrix waste into small, manageable pieces that flow smoothly through ductwork, preventing blockages. Oil misters and duct coatings ensure PSA materials do not adhere to surfaces, while custom rotor designs mitigate material jams.

- Stop Matrix Waste Winding—Our systems capture waste directly at the press, eliminating the need for winding matrix rolls, reducing stoppages and preventing unnecessary material wastage.

Cost savings & waste reduction

PAC systems optimise material use and reduce operational costs.

- Thinner Edge Trim – Capture trim as thin as 1/8 inch to maximise material efficiency.

- Fewer Press Stops – By eliminating matrix winding, presses no longer require frequent stops for waste roll removal, saving material and time.

Lower Virgin Material Costs – Our Granulate Feed System (GFS) enables a high scrap-to-virgin resin ratio, reducing costs while maintaining product quality.

Automated waste handling for lower labour costs

PAC’s automated solutions minimise the need for manual waste handling, allowing companies to streamline operations and reduce labour expenses.

- Automated Trim and Matrix Collection – Reduces reliance on manual labour in printing, labelling, and converting processes.

- Densified Waste – Inline cutter/fan systems chop the waste into small pieces, making handling easier and reducing waste volume. Eco-PAC balers and waste densifiers further compact waste for efficient transport.

Learn more about the trim and matrix removal system

Precision AirConvey (PAC) is an industry-leading pneumatic waste removal solution that is available exclusively in the North American market as part of the Envac Group.

Trim and Matrix Removal

PAC’s advanced trim and matrix waste removal solutions offer industrial manufacturers, printers, and converters a smarter way to manage production waste. By automating waste collection and densification, our systems increase productivity, reduce downtime, and support sustainable manufacturing practices.

Additional environmental and cost benefits

Fewer Landfill Trips – Densified waste occupies less space, reducing disposal frequency and landfill costs.

Energy-Efficient Equipment – PAC’s high-speed yet low-horsepower engineering reduces energy consumption, lowering electricity costs and carbon footprint.

Ready to optimise your industrial operations? Contact PAC today to learn how our advanced waste removal solutions can help your business.

Don’t take our word for it.

Here are words from some happy PAC Customers.

The Intermediate Trim System Integration Project is complete. The installation was flawless. We incurred minimal downtime in production.

This reflects one thing to me: The design and engineering of the system was well thought out. The installation crew installed the system methodically and with attention

to detail. All the guys performed the installation safely and worked well with our

Production Team. Ron made sure any and all concerns were addressed while working at heights and included our operators when his team had to impede into their production

work zone.I look forward to working with this same team in our future projects. Great job to the PAC Team!!!!!! Thank you for a safe and successful installation.

Scott Ford Electrical Designer, Sealed Air

PAC is a great company to work with as they are always very attentive to our business needs. Their system is both efficient and effective and requires low maintenance.

Brian Gale President, I.D. Images

The PAC system has made a substantial contribution to keeping the work environment clean and unclut- tered.

Bob Hackman Diversified Labeling Solutions

Thank you for all the hard work you did for us. We are thrilled with everything. PAC is a wonderful company to work with.

Jen Trello Plant Manager, ID Technology

I wanted to take a few moments and thank Precision Air Convey for the outstanding job just completed at our facility. The project from start to completion was as professional as can be with the highest quality of work. It has already shown a great improvement to our production output and we have some happy employees not having to deal with drum vacuums anymore. Thanks to your team for this great job!

Tom McClintock Facility Maintenance Manager, Trelleborg Streamwood

By installing an automated trim removal system from PAC, I instantly provided a cleaner, safer environment; opened up floor space: cut labor costs; and streamlined my recycling initiative.

Dan Leverington JP Morgan Chase

Everyone claimed they could handle our trim requirements. Only PAC would guarantee to handle our trim without plugging.

Ron Engebos Fox Converting

PAC has always been with me to resolve my issues regarding raw material reclamation to lower my manufac- turing costs. I explain the issue and they engineer the issue out of my process.

Mike McSherry Mint-X Corporation