The brief

The municipality of Oslo aims for a circular waste system. The amount of recycled waste is to reach 50% before 2019 and household waste sorting is mandatory.

About 80% of the inhabitants in Oslo live in multi-family housings or terraced houses so space for adding more bins is very limited.

The solution

Considering the limited space for more bins and the amount of heavy transport in Oslo the choice fell on optical sorting.

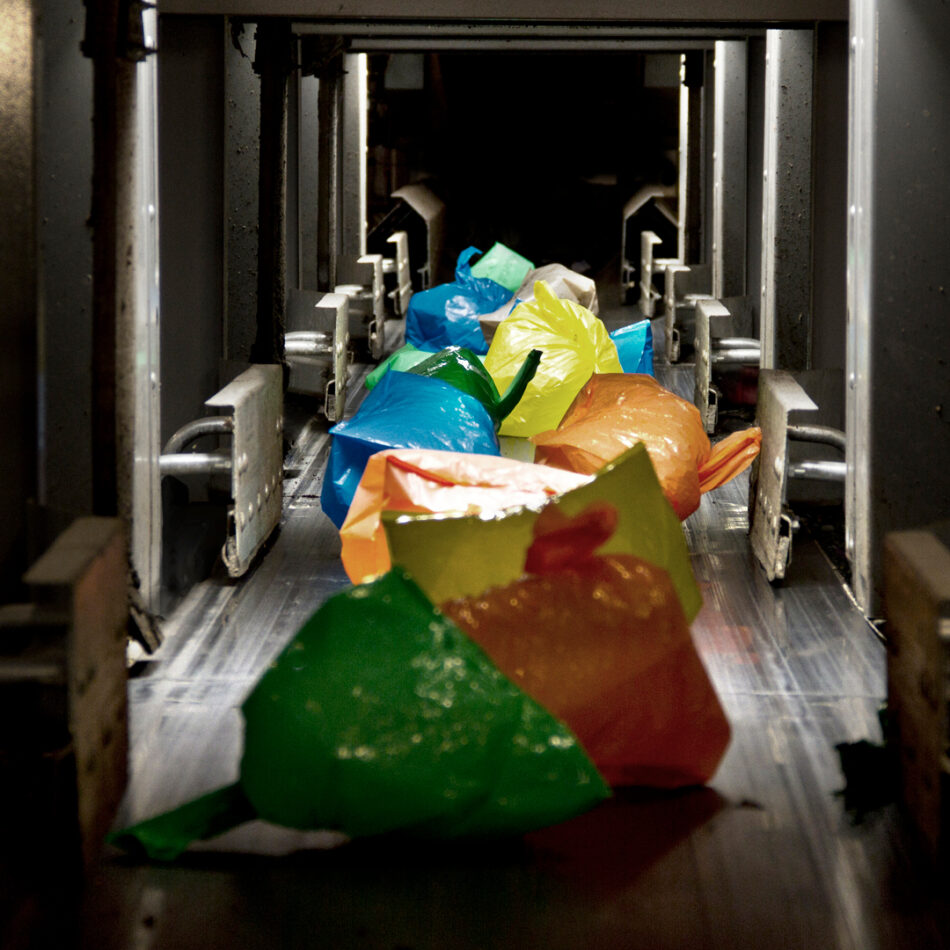

Using Optibag’s system the municipality could keep the same bins and the same vehicles could be used while the transports could be kept at a minimum.

The two sorting plants owned by EGE (Energy Recycling Administration) have three fractions: food waste, plastics and other materials.

Food waste becomes biogas and biofertilizer, while plastic is recycled and the rest fraction is energy recycled.

The two plants use pre-treatment sifts to remove any non-bagged materials aswell as a wind sift to refine the plastic fraction after sorting. In 2017 46.4% of all food waste in Oslo was sorted in the green bags, which is the best result in Scandinavia.

Capacity 180 000 tons/year

Resources Food, Plastics and Rest

Users 650 000

Development

In 2009 the first optical soring plant (Haraldrud) was opened in Oslo. With that, Oslo became the first major city in Scandinavia to introduce the system.

In 2012 the second plant (Klemetsrud) was deployed. The entire municipality was now using optical sorting.

In 2013 EGE together with Optibag developed post-treatment techniques for the plastic fraction in order to refine the material further.