Hospitals face unique waste management challenges—limited space, constant activity, and high hygiene demands. Traditionally, waste and soiled linen are stored locally in the wards and transported in corridors and elevators. Patients and healthcare professionals risk exposure to both pathogens and odours.

By using fully automated collection through sealed pipes hidden in walls and ceilings, colony-forming unit (CFU) levels in the healthcare environment are minimised, and risks for cross-contamination are eliminated, helping to prevent and reduce risks of healthcare-associated infections (HAIs).

3-6 Years ROI

.

49% lower infection risk

Increased health & safety

5 fractions

Reducing the spread of infection with infectious waste collection (IWC)

Every year, hospital-acquired infections (HAIs) pose a serious risk to patient safety and cost hospitals millions. Traditional waste handling processes – whether manual or through automated guided vehicles (AGVs) – are still prone to spreading bacteria and contaminating high-traffic areas in a hospital. Automated waste collection and segregation at the source minimise human exposure to hazardous substances. It also prevents odours and potentially disease-carrying nuisances around the waste. The solution minimises the risk of cross-contamination between waste, patients, healthcare staff, and the hospital environment. For example, an Envac system installed in a French hospital transports and separates treatment of type III sharp, infectious waste with on-site sterilisations (scalpels, needles, and any metal/sharp material responsible for transmitting diseases).

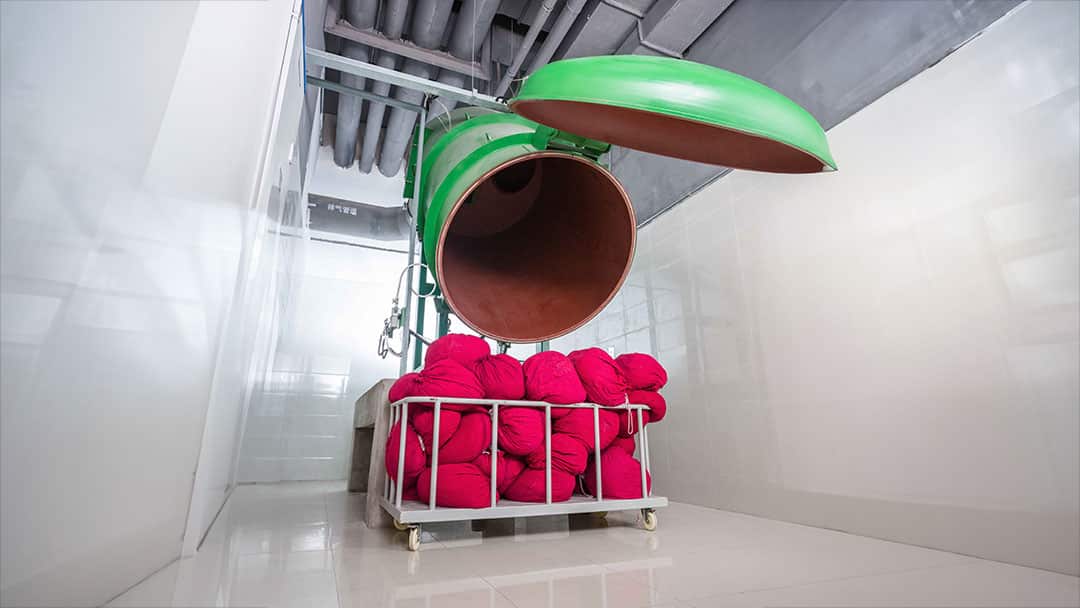

Improving logistics and safety with soiled hospital linen collection

With large volumes of soiled linen and waste generated daily, hospitals must have a reliable system in place to handle collection and disposal swiftly and safely. Envac’s automated linen collection system optimises hospital logistics by reducing manual handling, streamlining waste flow, and ensuring 24/7 hygienic and secure disposal. Hospitals can improve efficiency, free up resources, and create a safer working environment by minimising staff involvement in waste transportation.

A study by KTH University in Sweden found that hospitals using closed pipe systems for soiled linen and waste disposal had significantly lower bacterial contamination levels than those relying on traditional handling methods. The findings revealed that hospitals equipped with the Envac system recorded a 49.3% lower average CFU* count and a 6.10% lower median CFU* count, demonstrating a marked reduction in microbial presence.

By automating linen collection, hospitals can streamline operations, improve infection control, and maintain a cleaner, safer environment for both staff and patients.

(*CFU: Colony-Forming Units, a measure of bacterial presence.)

Strengthening hospital reputation and ensuring regulatory compliance

Hospitals must adhere to strict infection control and hygiene regulations set by bodies such as the NHS, WHO, and local health authorities. Traditional waste handling methods increase the risk of contamination due to manual contact. Envac’s automated system reduces human involvement, minimising infection risks and ensuring safer waste disposal. A closed pipe system prevents airborne contamination, improves waste segregation, and supports regulatory compliance. Beyond compliance, a well-maintained and hygienic environment enhances public trust, reassures patients, and fosters a positive reputation. By eliminating visible waste accumulation, reducing odours, and creating a cleaner facility, hospitals can improve patient satisfaction and staff working conditions. Many hospitals are required to adopt eco-friendly waste management practices to minimise their environmental impact. Envac’s system reduces carbon emissions by replacing frequent manual waste transport with an automated collection system, cutting down vehicle movements and energy use.

Reducing costs and maximising ROI with automated waste management

Investing in Envac’s automated waste collection system delivers long-term cost savings and operational efficiency for hospitals. The system lowers labour costs by reducing manual handling, allowing staff to focus on patient care rather than waste transport. With fewer waste-related vehicle movements, hospitals also save on fuel, maintenance, and staffing expenses. A study by KTH University in Sweden found that hospitals using Envac’s closed system had significantly lower bacterial Contamination, reducing infection risks. This helps hospitals avoid costs associated with infection outbreaks, such as additional cleaning, sterilisation, and compliance measures.

Hospitals typically recoup their investment within a few years (approx. 3 to 6 years) through operational savings, improved infection control, and reduced waste management expenses. By integrating Envac’s system, healthcare facilities create a cleaner, safer, and more cost-effective environment, ensuring long-term financial and environmental sustainability.

Healthcare waste & associated risks

Urgent need for smart waste collection system

Manual Waste Handling = Hygiene Risk

Exposure increases infection risk for staff and patients

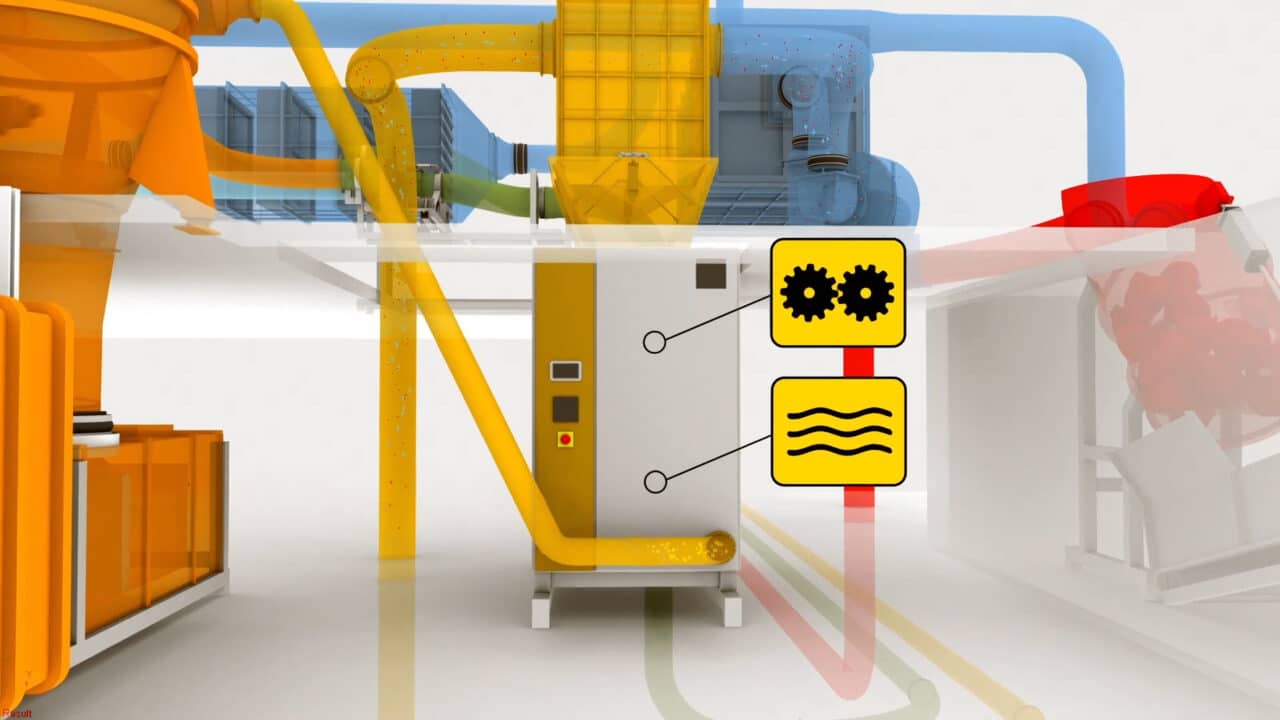

Air inlet

Air inlet valve for the infectious waste transport pipe.

Inlet point

The number of inlet points and their location are defined by the functions of the hospital. Green pipe for general hospital waste and recyclables Red for soiled linen.

The inlets can be fitted with touchless technology that uses sensors for access control. The sensors recognize if it is waste, recyclables, laundry, or infectious waste, that is being disposed of.

Without any physical contact with buttons, handles, or panels to dispose of the waste, the spread of infections is minimized.

Infectious waste

Infectious waste is collected in a separate, hermetically sealed pipe (yellow pipe).

The closed system and touchless waste inlets minimize the spread of infections, direct transmission, and accidents.

Air inlet

Air inlet valve for waste and linen transport pipes.

Pipe network

The pipe network runs from the inlet points to the collection station hidden behind walls, in ceilings and in the service corridors.

This ensures that the system remains discreet and unobtrusive while saving valuable square footage which can be utilized for other purposes.

Automatically controlled

All processes are automatically controlled by Envac’s own development Envac Automation Platform (EAP).

Collection station

All materials are collected at one single point. The collection station is typically located in the technical area at the back of the hospital.

Soiled linen bags drop

Soiled linen bags drop into containers for transport to laundry facility.

Infectious waste

Infectious waste is collected in a separate, hermetically sealed pipe (yellow pipe).

The closed system and touchless waste inlets minimize the spread of infections, direct transmission, and accidents.

Containers

Full containers are taken to the recycling center and returned empty.

Solutions for Healthcare

Envac offers a range of automated waste collection systems specifically designed for hospital environments to boost hygiene, safety, and operational efficiency. These solutions can be implemented individually or combined into a comprehensive hospital waste management system.

Stationary Pneumatic Waste Collection System

Traditional waste handling takes up valuable space and risks cross-contamination in the hospital environment. Envac optimizes hospital waste management by hygienically transporting it with a sealed vacuum system to a central collection point. Smart multi-fraction inlets simplify sorting, reduce manual handling, improve hygiene, and save space, labor, and operational costs.

Soiled Linen Collection System

Handling soiled linen risks exposing staff and patients to airborne pathogens, and heavy bags can cause strain-related injuries over time. Frequent transport through corridors and elevators negatively disrupts hospital logistics, decreasing accessibility. Envac’s 24/7 smart linen collection system minimizes physical contact, supports infection control protocols, and maintains a clean, efficient, and compliant

environment.

Infectious Waste Collection System

Managing hazardous hospital waste – especially infectious and sharps waste – demands strict routines, special containers, and detailed labelling. Transport must follow strict safety protocols. Envac simplifies this by enabling near-source disposal and enclosed pipe transport to an on-site treatment facility, converting it into non-hazardous waste. The result: safer handling, higher efficiency, full compliance, and lower costs.

Kitchen Waste Collection System

Envac’s kitchen waste solution eliminates the need for bins and bags by allowing direct disposal of waste into inlets integrated within the food preparation area. The waste is then swiftly transported through vacuum-sealed pipes to a central collection unit, removing transport paths and ensuring a clean, odour-free kitchen that complies with the most stringent hygiene requirements.

Related Projects

Healthcare Atlanta, Georgia

Children’s Healthcare of Atlanta

Consistently ranked among the top children’s hospitals by U.S. News & World Report the hospital’s green and sustainable focus reaches new heights with an automated pneumatic waste removal system

Healthcare Montreal, Quebec Canada

Jewish General Hospital

The Jewish Hospital in Montreal is a wonderful example of consistent modernization. Envac North America has created and installed an innovative waste and linen removal system to help with sustainability, efficiency, infection control and improved patient outcomes.

Healthcare Beijing, China

General Hospital of People’s Liberation Army

Beijing 301 hospital is known as one of the premier hospitals in China. Since 2009 two Envac systems solves the collection of general hospital waste and soiled linen. The systems are exclusively designed for Beijing 301 hospital. They are environmentally friendly, safe and hygienic.

Related Articles

The True Cost of Manual Waste Handling in Hospitals

The True Cost of Manual Waste Handling in Hospitals Hospitals face constant pressure to improve safety, reduce costs, and create cleaner environments for patients and /../

Automating Clean: How Waste Technology is Reshaping Hospital Hygiene

Automating Clean: How Waste Technology is Reshaping Hospital Hygiene Hospitals have always been built around care. Yet behind the scenes, one of the most overlooked /../

The True Cost of Manual Waste Handling in Hospitals

Hospitals face constant pressure to improve safety, reduce costs, and create cleaner environments for patients and staff. Yet one area often overlooked is waste management. /../